FUTABA

We aim to satisfy required levels

of accuracy and quality

through technical expertise and

systematizing our production system.

Futaba Seisakusho mainly manufactures precision rubber molds.

We have systematized our production structure, enabling us to supply high-quality and short-term molds that require advanced technology and precision, and we carry out almost all production activities in-house, starting from material procurement.

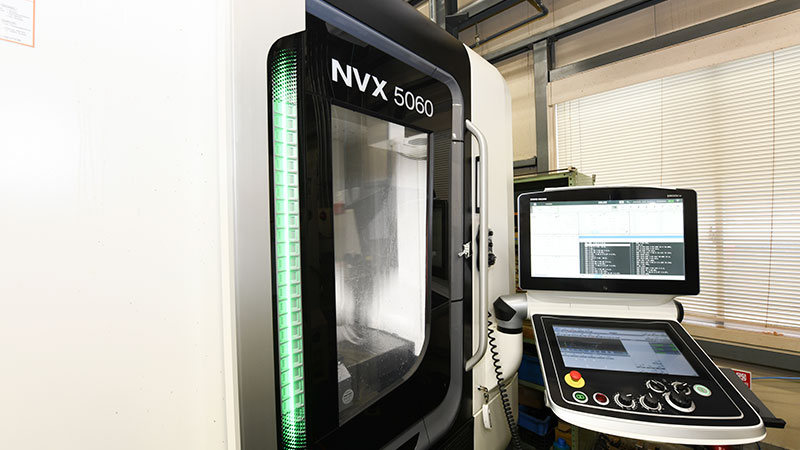

We have also introduced a number of state-of-the-art machine tools to improve productivity and achieve required levels of accuracy.

To ensure quality control, it is essential to check each process not only using equipment, which we do as a matter of course, but also human inspection to detect tiny discrepancies visible to the human eye, discomfort when touching, and so on.

Seeking the highest quality, we utilize the strengths of both human and machine.

Furthermore, we ensure each employee participates in all kinds of training and study groups to improve his or her skills. We incorporate the results of this training into our business as new technical expertise.

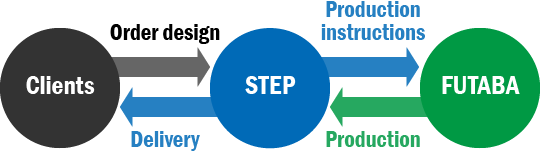

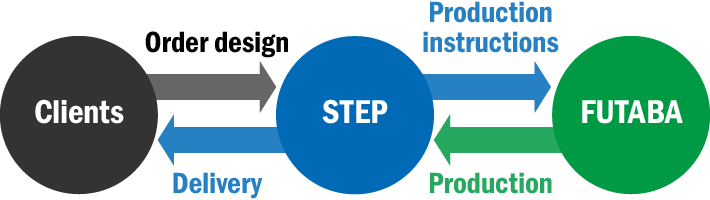

In addition, documents and other materials required for work are shared with Step through our unique system, which means that drawings, data, and work processes are constantly checked and amended on site, leading to better work efficiency and higher quality.

Product Line

List of main equipment used

- Machining center

- High-speed machining center

- NC milling machine

- NC electrical discharge machine

- Wire electric discharge machine

- NC lathe

- Surface grinding machine

- Form grinding machine

- General-purpose milling machine

- General-purpose lathe

- Radial drilling machine

- Tabletop drilling machine

- Microscope

- Projector

- Molding press

- CAD/CAM

- Process management system

- Three-dimensional measuring instrument

- Surface roughness measuring instrument

- CNL image measurement system

- Automatic blade forming machine

- Tool grinding machine